Export-oriented conveyor loader

The conveyor loader is mainly used in cave mining operations with narrow spaces, such as metal mines, water diversion roadways, etc. Its function is to collect, transport and load gravel and slag materials into vehicles for various projects.

Features of Zhongliang's export-oriented conveyor loader

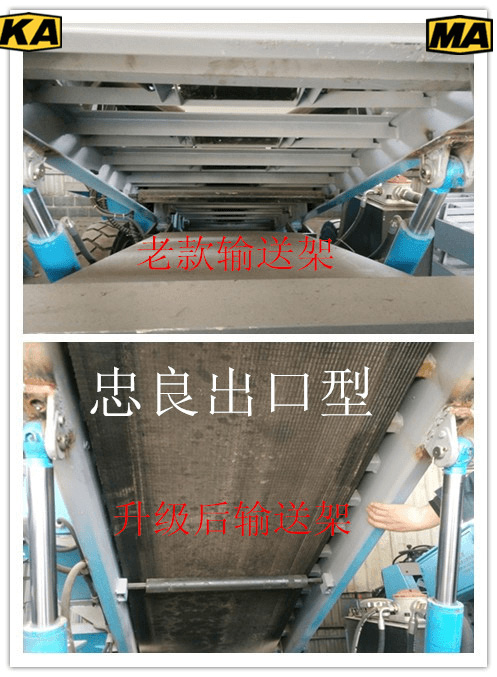

Due to the extremely harsh working conditions for the operation of a conveyor loader, usually there is heavy dust, deep water, hard mineral materials, etc. The bearing of the driven roller of the conveyor loader is easy to wear and rust, thereby affecting the service life of the bearing. At the same time, the mineral material might be too hard so it is easy to cause deformation of the front section of the conveyor frame. Therefore, the channel steel conveyor frame is upgraded instead to a rectangular tube conveyor frame. The upgraded conveyor rack has the following characteristics:

After the driven roller is improved

1. The upgraded driven roller has passed the waterproof test to meet the waterproof and dustproof requirements, and the sealing pressure can reach more than 3MPa. This resolves the phenomenon of bearing wear, rust and necrosis which is caused by the original bearings since they are not waterproof and dust-proof. This upgraded design may improve the service life of the bearings.

2. After the upgrading, the bearing can be filled with grease at once, which can meet the requirement of one year's operation, and thus solves the problem that the original driven roller bearing is difficult to be filled with oil.

3. The upgraded driven roller installation method is changed from outside the conveyor frame to inside the conveyor frame to improve the strength of the driven roller shaft and increase the service life of the conveyor frame.

After the channel steel is upgraded and optimized to a rectangular tube:

1. The upgraded conveyor frame makes it possible not to open the installation hole of the driven roller, which increases the strength of the conveyor frame.

2. The overall beam of the conveyor frame adopts a rectangular tube to increase the bending strength of the entire conveyor frame.

3. The conveyor adopts a rectangular tube, which reduces the amount of welding in the manufacturing process and thus avoids welding deformation caused by welding.

4. The service life is increased by more than 3 times.

Conveyor System: The mature and stable hydraulic motor is used as the transmission power.

Axle: The axles are selected from construction vehicle manufacturers Zoomlion and Dongfeng, and the quality is guaranteed.

EN

EN  ES

ES RU

RU FR

FR PT

PT العربية

العربية

Tel: +86-0710-3337567

Tel: +86-0710-3337567 WhatsApp: +86-19972252417

WhatsApp: +86-19972252417 Fax: +86-0710-2510617

Fax: +86-0710-2510617

Home

Home Email

Email Product

Product

Welcome to send your message to us